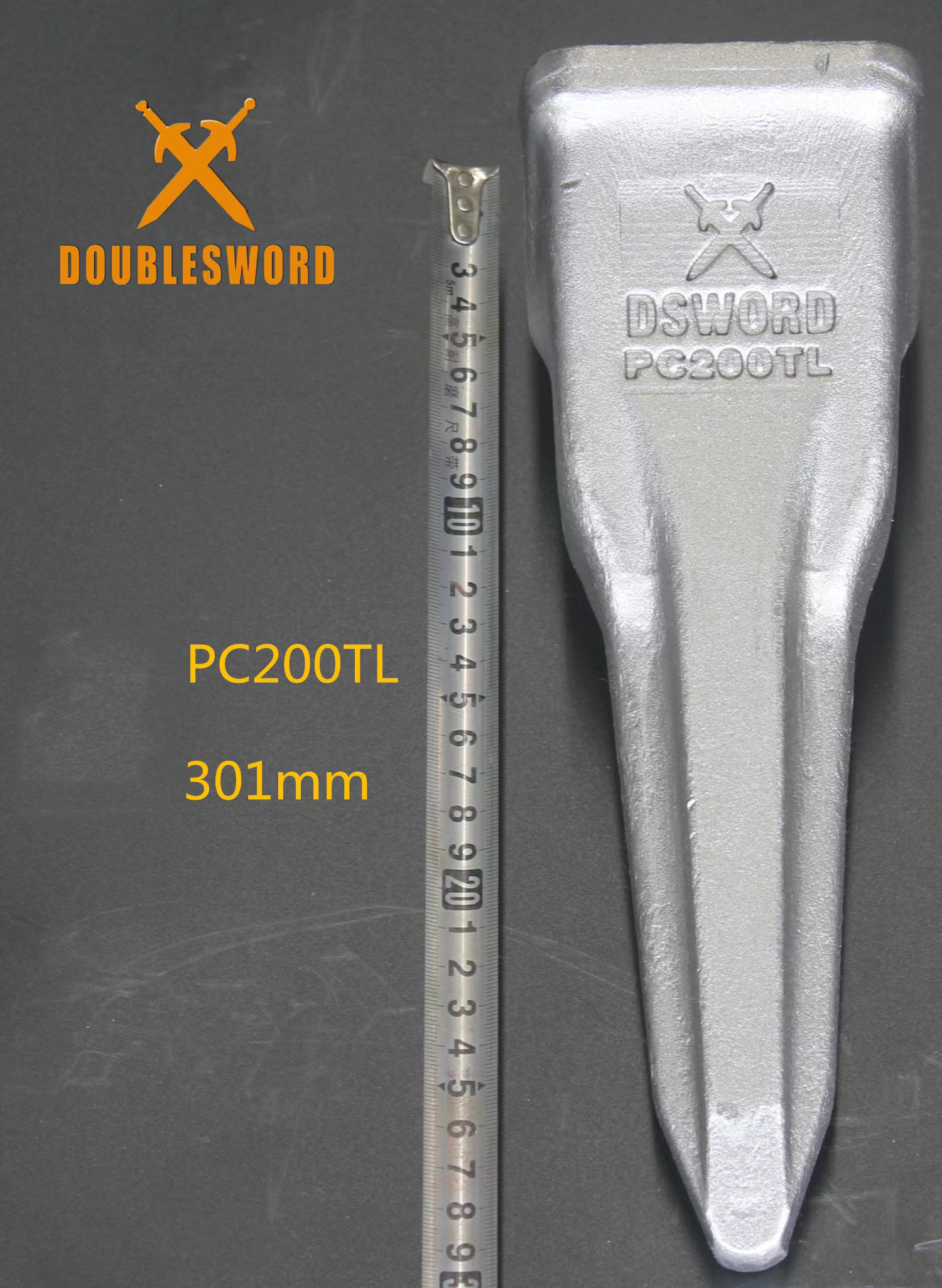

Tshuab txiav hniav thoob thoob (excavator thoob thoob hniav forging khoom siv)Cov Hniav Thoob Nqe Lag Luam Wholesale

Cov txheej txheem forging thiab casting ntawm cov hniav thoob:

Kev Forging: Nws yog tsim los ntawm kev extrusion nyob rau hauv qhov kub siab. Nws tuaj yeem ua kom cov noob ntoo hauv cov khoom, nrog rau sab hauv ntom thiab kev ua tau zoo. Nws yuav tsis ua rau muaj kuab paug rau ib puag ncig.

Kev Ua Pwm: Cov hlau ua kua uas yaj lawm yuav ua rau pwm txias. Qhov porosity yooj yim tshwm sim hauv nruab nrab ntawm cov khoom ua haujlwm. Cov txheej txheem tsim khoom yuav ua rau muaj kuab paug rau ib puag ncig loj heev.

Cov hniav thoob siv cov tshuab forging los ua kom muaj zog rau cov hlau tshwj xeeb, extrude lawv ntawm qhov kub siab, ua kom cov khoom siv siv lead ua hauv forgings, thiab ua rau lawv yas deformation kom tau txais qee yam khoom siv kho tshuab. Tom qab forging, cov hlau tuaj yeem txhim kho nws cov qauv, uas tuaj yeem ua kom ntseeg tau tias cov hniav thoob muaj cov khoom siv kho tshuab zoo, tiv taus hnav ntau dua, thiab lub neej ntev dua. Kev casting yog yaj cov hlau ntawm qhov kub siab, ntxiv cov khoom siv pabcuam, txhaj tshuaj pwm, thiab tau txais kev casting tom qab solidification. Kev casting tsim los ntawm cov txheej txheem no yooj yim los tsim cov qhov cua thiab tsim cov qhov xuab zeb, thiab nws cov khoom siv kho tshuab, tiv taus hnav thiab lub neej kev pabcuam qis dua li cov ntawm forgings. Cov Hniav Thoob lag luam wholesale nqe

Cov hniav thoob feem ntau muab faib ua cov hniav thoob casting thiab cov hniav thoob forging raws li lawv txoj kev tsim khoom. Kev ua tau zoo ntawm ob txoj kev tsim khoom sib txawv. Feem ntau hais lus, cov hniav thoob forged yog cov khoom siv uas tsis yooj yim hnav, tawv dua, thiab muaj lub neej ua haujlwm ntev dua, uas yog ob npaug ntawm cov hniav thoob casting, tab sis tus nqi tsuas yog 1.5 npaug. Cov hniav thoob yog cov khoom tseem ceeb ntawm cov excavators thiab forklifts. Niaj hnub no, cov hniav thoob forged tau siv dav. Cov hniav thoob forging yog extruded los ntawm forging hydraulic xovxwm (kub forging hydraulic xovxwm, kub tuag forging roj xovxwm) los ntawm lub pwm.

Lub tshuab ua kom cov hniav thoob (cov khoom siv ua kom cov hniav thoob) siv cov thev naus laus zis electro-hydraulic proportional los tswj cov siab, ceev thiab mob stroke, thiab tuaj yeem tswj tau qhov loj ntawm cov forging. Nws siv lub xub pwg nyom ua ke nrog kev ruaj khov zoo. Txhua lub tog raj kheej roj yog cov tog raj kheej plunger, thiab lub rooj ua haujlwm txawb tau ruaj khov hauv kev hloov pauv, nrog rau lub cuab yeej buffer. Cov khoom siv kuj tseem siv tau rau kev txias thiab kub forging ntawm cov hlau, nrog rau cov txheej txheem nias ntawm cov khoom siv yas. Nws tuaj yeem ua tiav kev forging dawb, tuag forging thiab lwm yam txheej txheem.

Cov kauj ruam kub forging txheej txheem ntawm cov hniav thoob excavator:

Kauj Ruam 1: Cov txheej txheem blanking siv precision blanking, thiab qhov kev kam rau siab ntawm qhov ntev blanking yog ± 0.5 hli.

Kauj Ruam 2: Cov txheej txheem cua sov siv qhov nruab nrab zaus induction cua sov ntawm 1150 ℃ kom cua sov qhov chaw ua haujlwm sai sai thiab txo qhov tsim ntawm oxide nplai.

Kauj Ruam 3: Thaum lub sijhawm ua kom tawg, tshem tawm cov tawv nqaij oxide nyob ib puag ncig qhov tawg, thiab tib lub sijhawm tshem tawm cov tawv nqaij oxide sab saud thiab sab qis nrog cua tshuab, kom txhim kho qhov zoo ntawm cov forgings thiab lub neej ua haujlwm ntawm cov pwm, thiab xyuas kom meej tias qhov sib piv ntawm qhov ntev ntawm qhov tawg rau txoj kab uas hla tsawg dua 2.5 thaum lub sijhawm ua kom tawg.

Kauj Ruam 4: Hauv cov txheej txheem kaw cov khoom sib xyaw extrusion, lub pwm sab saud txav mus nrog lub thaiv swb ntawm lub thoob hniav forging tsim xovxwm (excavator thoob hniav forging khoom siv) kom nias lub pob kom txog thaum txhua qhov chaw puv nrog hlau. Lub thoob hniav dawb paug yog tsim los ntawm kev swb cov khoom sib xyaw extrusion ntawm lub pwm sab saud hauv pwm. Lub thaiv swb ntawm lub xovxwm rov qab los, ejects cov khoom extrusion tsim, thiab tag nrho cov txheej txheem extrusion tiav. Thoob Hniav lag luam wholesale nqe

Cov txheej txheem forging tshwj xeeb ntawm cov hniav thoob:

Cov hlau puag ncig raug cua sov rau qhov kub uas xav tau rau kev forging tom qab blanking raws li qhov loj me, thiab tom qab ntawd nws tau muab tso rau hauv kab rov tav hauv qhov chaw ua ntej forging rau forging thiab tom qab ntawd tig 90 ° rau forging dua. Qhov chaw ua ntej forging yog tiaj tus nrog ib kawg tuab thiab ib kawg nyias. Qhov kawg nyias ntawm qhov chaw ua ntej forged blank yog tso ntsug rau hauv qab hauv qhov chaw ua ntej forging. Lub wedge punch faib thiab extrudes qhov chaw dawb mus rau hauv qab. Tom qab 4 txog 5 zaug ntawm forging, qhov chaw dawb yog tsim rau hauv qhov chaw forging, Tom qab ntawd, qhov chaw forging yog machined thiab cua sov kho. Qhov chaw dawb yog ua tiav rau hauv ib lub wedge zoo ib yam li cov hniav thoob los ntawm kev ua ntej forging. Tom qab ntawd, lub groove ntawm cov hniav thoob hauv paus yog tsim los ntawm kev faib thiab extruding cov hniav thoob hauv paus nrog lub wedge punch thaum lub sijhawm kawg forging. Cov nyhuv tsim yog zoo, qhov demoulding yog yooj yim, thiab cov txheej txheem ua haujlwm yog siab. Ntxiv mus, kev ua haujlwm kho tshuab ntawm cov hniav thoob yog zoo dua li cov khoom ua tiav los ntawm kev casting. Los ntawm kev ua kom zoo dua ntawm qhov ua ntej forging qhov thiab qhov kawg forging qhov, qhov kev tso cai machining me me thiab tus nqi ua tiav qis, Kev siv hluav taws xob tsawg, tsis muaj kuab paug rau ib puag ncig.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-28-2022